E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

2025-04-16 16:36:41

Pre treatment: including picking, sorting, cleaning, and disinfection.

Peeling: Manual or mechanical peeling, usually using hot alkaline solution for peeling treatment.

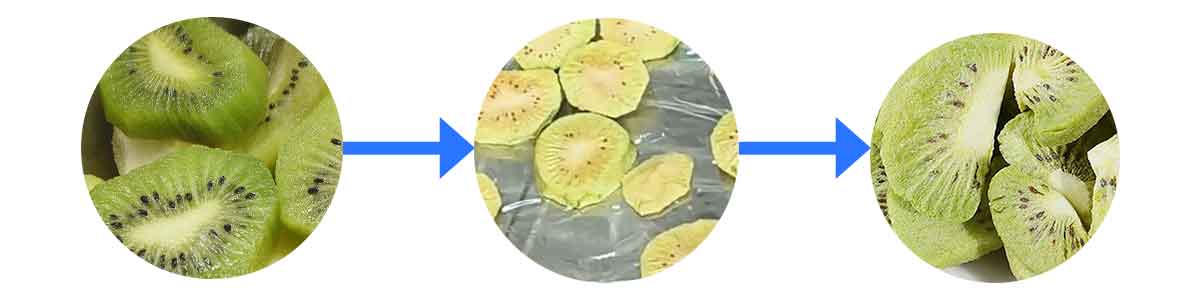

Slicing: Cut the peeled kiwifruit into 4mm thick uniform slices along the longitudinal direction of the fruit.

Color protection: This step can prevent kiwi slices from changing color during processing.

Plate: Spread the cut kiwi slices evenly in the material tray.

Pre freezing: Place the kiwi slices on a tray in an environment of -35 to -25 ℃ for pre freezing for 4 to 7 hours.

Vacuum freeze-drying: Quickly perform vacuum freeze-drying on pre frozen kiwi slices at a temperature of -60 to -55 ℃ for 10-15 hours. During the drying process, it is necessary to control the vacuum degree and heating plate temperature. In the initial stage, to provide sublimation heat to accelerate water overflow, the heating plate temperature is set to 70 ℃. During the strong dehydration period, the temperature is set to 60 ℃, and at the end of the drying period, the temperature is set to 50 ℃.

Desorption drying: After the sublimation drying stage is completed, continue to raise the temperature to 25 ℃, set the heating plate temperature to the required value for the experiment, and when the center temperature of the material approaches the layer temperature, the drying process ends.

Packaging: Seal and package the freeze-dried kiwi slices to prevent them from becoming soft due to moisture in the air, which may affect their crispy texture.

Previous: no more

Next: Freeze Dried Pet Food

Contact Us

Request a Quote

Links:

Copyright © Shandong Heying Machinery Technology Co., Ltd. 2024 All rights reserved