E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

PROADUCT LIST

20m² Vacuum Freeze Dryer

Product Description

Commercial freeze dryer, also known as a lyophilizer, is a specialized piece of equipment used to remove water from perishable materials, such as food, pharmaceuticals, and biological samples, by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This process, known as freeze-drying or lyophilization, helps to preserve the material while maintaining its structure, flavor, and nutritional value.

20 m² Vacuum Freeze Dryer Paraeter

Drying Chamber Size | 20 m² |

| Freezing Capacity | 200-300kg |

| Over Dimension | 7.5x1.7x2 |

| Freezing Trays | 48pcs |

| Tray Size | 610x710x37mm |

| Total Power | 56kw |

| Control Method | PLC automatic |

Freeze Dryer Detailed Parts Information

The air dryer system consists of a refrigeration system, a vacuum system, a heating system, and an electrical instrument control system. principal part.The components include drying oven, water trap (cold trap), refrigeration unit, vacuum pump, heating/cooling device, etc.

1.Lyophilizer Radiation Tray

The heat medium in the heating system is electric heating, and the heat medium is silicone oil. The heat transfer efficiency is high, the heat transfer performance is stable, and the cost is saved.

2.Freeze Dryer Cold Trap

The cold trap is used to capture the sublimated water vapor. The ice- capturing ability of the cold trap in the freeze dryer directly affects the vacuum degree in the chamber. In the early stage of freeze drying, the sublimation amount is large, requiring the ice-capturing ability of the cold trap to be strong. With the decrease of the sublimation amount, the demand for the ice-capturing ability of the cold trap also decreases.

3.Vacuum System

The vacuum system is designed to quickly evacuate the drying chamber after material enters, and to maintain and control the vacuum level within the drying chamber during the freeze-drying process. For freeze-dryers equipped with a condenser, the vacuum pump primarily removes non-condensable gases and trace amounts of water vapor. The vacuum pump maintains the vacuum level in the drying chamber and adjusts the vacuum to meet process require- ments through the condenser, valves, and vacuum monitoring equipment.

Commercial Freeze Dryer Freeze-Drying Process

1.Pre-treatment Process

Different materials require different pre-treatment methods. Based on the characteristics of the raw materials, appropriate pre-treatment methods are used. For example, in the pre-treatment of frozen dried vegetables, in addition to sorting, cleaning, and cutting, blanching is also required. After blanching, the vegetables need to be cooled quickly, drained, and then placed on trays. For fruit pre-treatment, the main focus is on protecting the color, with varying processing techniques.

2.Pre-freezing Process

There are two methods of pre-freezing: vacuum evaporation freezing and freezing with rapid freezing equipment. In order to ensure the quality of food, the latter is generally selected. The pre-freezing temperature is selected according to the eutectic point temperature of the frozen material, and the structure and shape of the frozen material are selected accordingly Size, select the freezing time. According to the properties of the material, select the pre-freezing rate. The pre-freezing process direc- tly affects the quality of the material.

3.Sublimation Drying

Sublimation drying is carried out in a vacuum apparatus, so maintaining the appropriate vacuum level during the sublimation process is crucial. To enhance the sublimation rate and shorten the freeze-drying time, it is necessary to appropriately increase the sublimation temperature, improve heat transfer efficiency, and reduce the resistance of water vapor escape. Howev- er, the sublimation process and temperature are subject to the following conditions: the temperature of the frozen part must be below the eutectic point; otherwise, the frozen part will melt. The dried part forms a framewo- rk, which becomes less rigid and sticky, leading to collapse. If too much heat is supplied, the product will melt and become unusable.

Advantages of Vacuum Freeze-drying Technology in the Food industry

1. Maintain the nutritional content and taste of food: Vacuum freeze-drying technology can be carried out at low temperatures, avoiding the damage of high temperatures to the nutritional content of food, while maintaining the original taste and color of food.

2. Extended shelf life: After removing moisture, the growth of microorganisms in freeze-dried food is inhibited, thereby extending the shelf life of the food.

3. Convenient storage and transportation: Freeze dried food has the characteristics of being lightweight, easy to store, and easy to transport, which reduces the cost of food production and circulation.

4. Increasing the added value of food: Food processed through vacuum freeze-drying technology has a unique flavor and taste, which can meet consumers' demand for high-quality food and thus increase the added value of food.

Application

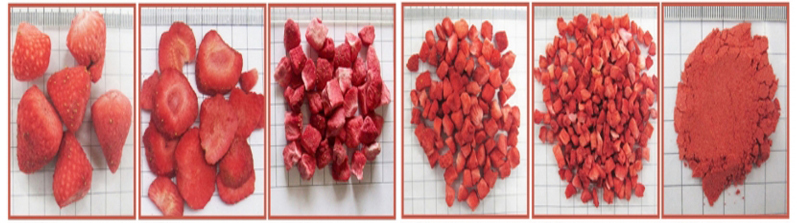

1. Freeze drying of fruits and vegetables: Freeze drying of fruits and vegetables is the process of using vacuum freeze-drying technology to remove moisture from fresh fruits and vegetables after pretreatment, resulting in dried fruits and vegetables. This dried fruit and vegetable product maintains the nutritional content, taste, and color of the original fruit and vegetable, making it easy to store and transport, while retaining the flavor and taste of the original fruit and vegetable.

2. Meat freeze-drying: Meat freeze-drying is the process of pre treating fresh meat and using vacuum freeze-drying technology to remove moisture, resulting in dried meat products. This type of dried meat has the characteristics of high protein, low fat, and rich nutrition, making it suitable as a convenience food or emergency food.

3. Seafood freeze-drying: Seafood freeze-drying is the process of pre treating fresh seafood and using vacuum freeze-drying technology to remove moisture, resulting in dried seafood products. This dried seafood maintains the flavor and taste of the original seafood while being convenient for storage and transportation, making it suitable as a high-end food or gift.

4. Seasoning freeze-drying: Seasoning freeze-drying is the process of processing various seasonings through vacuum freeze-drying technology to produce dried seasonings. This dried seasoning has the advantages of maintaining its original flavor, easy storage, and portability, making it convenient for consumers to use in their daily lives

Inquire Now

Contact Us

Request a Quote

Links:

Copyright © Shandong Heying Machinery Technology Co., Ltd. 2024 All rights reserved