E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

PROADUCT LIST

5m² Vacuum Freeze Dryer

Product Description

The freeze-drying of products needs to be carried out in a certain device called a vacuum freeze dryer, abbreviated as a freeze dryer.Freeze dryers are divided into four main parts according to their systems: refrigeration system, vacuum system, heating system, and control system. Divided by structure, it consists of a freeze-drying oven or drying oven, a condenser or water vapor condenser, a freezer, a vacuum pump and valve, electrical control components, etc.

5m² Freeze Dryer Basic Parameter

| Effective Shelf Area | 5m² |

Maximum Water Catchment | 75kg/batch |

| Voltage | Can be Customized |

Maximum Loading Capacity | 50-60k |

Installed Power | 15KW |

Overall Dimension | 2800*1400*1600mm |

Weight | 1900kg |

Working Principle

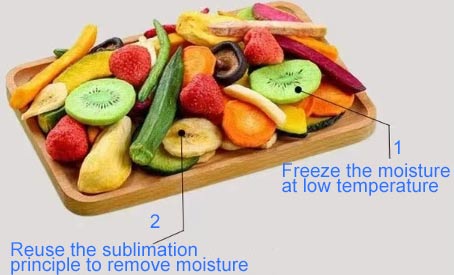

Freeze drying is a technique that utilizes the principle of sublimation for drying. It involves rapidly freezing the material to be dried at low temperatures, and then in an appropriate vacuum environment, allowing the frozen water molecules to sublime directly into water vapor and escape. The product obtained from freeze-drying is called Lyophilizer, and this process is called Lyophilization.

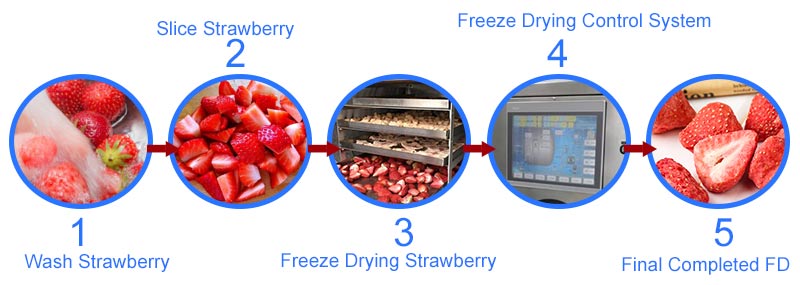

Vacuum Freeze Drying Process

1.Pre freezing stage. Place the material to be dried in a low-temperature environment, allowing the moisture inside to quickly condense into ice crystals. The key to this stage is to ensure uniform freezing of the material and avoid the formation of large ice crystals that can damage the structure of the material.

2.Vacuum stage. Start the vacuum system to reduce the pressure inside the drying chamber to an extremely low level. This low-pressure environment helps to lower the sublimation temperature of ice crystals and promote the subsequent sublimation process.

3.Sublimation stage. Under vacuum and appropriate heating conditions, ice crystals in the material directly sublime into water vapor, which is collected and discharged from the system through a condenser. During this process, the material temperature is kept below freezing point, avoiding material quality loss and nutrient damage caused by the presence of liquid water.

Small Freeze-Drying Machines Characteristics

1.Compact and portable. The small freeze-drying machine has a small volume, light weight, and is easy to carry and use.

2.Easy to operate.Most modern small freeze-drying machines use touch screens or rotary control panels, and users only need to set parameters such as temperature, time, and vacuum degree to start the equipment. Some high-end models are also equipped with intelligent control systems that can automatically adjust working parameters to meet the drying needs of different materials.

3.Efficient and energy-saving.By optimizing the heat conduction structure, adopting efficient vacuum pumps and refrigeration systems, small freeze-drying machines effectively reduce energy consumption and operating costs.

Application

Freeze dryers are widely used in multiple fields, including:

Medicine: Used to preserve bioactive substances such as serum, bacterial strains, traditional Chinese and Western medicine, etc.

Biological products: preserve bioactive substances.

Food: such as freeze-dried fruits and vegetables, can retain more nutrients and original flavors.

Chemical industry: used for drying dehydrated vegetables, wild vegetables and other materials.

Inquire Now