E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

PROADUCT LIST

1m² Vacuum Freeze Dryer

Product Description

Vacuum freeze dryer (freeze dryer) is a device that can directly sublime the moisture in materials from solid state to gas state under low temperature and vacuum environment, thereby achieving drying. Its working principle is based on the three state changes of water, namely the conversion between solid, liquid, and gas states. Specifically, the freeze dryer cools the material to freezing temperature through a refrigeration system, and then directly sublimates the ice into water vapor in a vacuum state to remove moisture from the material, ultimately obtaining dried material.

Small vacuum freeze dryer is a small-sized and easy to operate freeze-drying equipment, mainly used for laboratory research and household applications.1m² small freeze dryer has 4 pcs trays to carry materials for freeze-drying.

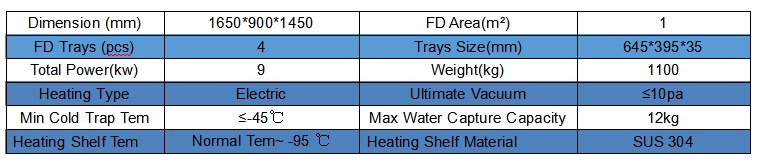

Basis Parameter

Working Principle

The basic principle of freeze-drying is based on the three state changes of water. Water can exist in solid, liquid, and gas states, which can both be converted and coexist with each other. When water is at the triple point (temperature of 0.01 ℃, water vapor pressure of 610.5Pa), water, ice, and water vapor can coexist and be in equilibrium with each other. Under high vacuum conditions, utilizing the principle of sublimation, the moisture in pre frozen materials is directly removed as water vapor through ice sublimation without melting, thus achieving the purpose of freeze-drying.

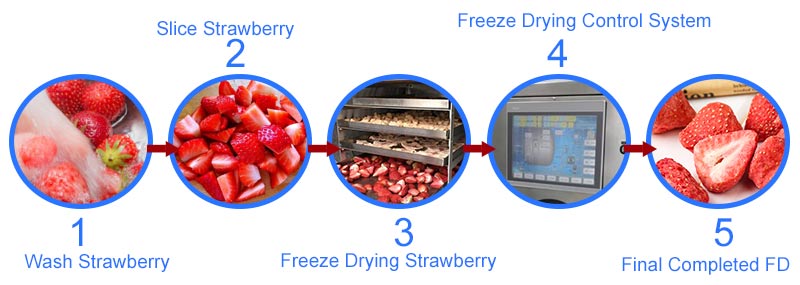

Vacuum Freeze Drying Process

1.Pre freezing stage. Place the material to be dried in a low-temperature environment, allowing the moisture inside to quickly condense into ice crystals. The key to this stage is to ensure uniform freezing of the material and avoid the formation of large ice crystals that can damage the structure of the material.

2.Vacuum stage. Start the vacuum system to reduce the pressure inside the drying chamber to an extremely low level. This low-pressure environment helps to lower the sublimation temperature of ice crystals and promote the subsequent sublimation process.

3.Sublimation stage. Under vacuum and appropriate heating conditions, ice crystals in the material directly sublime into water vapor, which is collected and discharged from the system through a condenser. During this process, the material temperature is kept below freezing point, avoiding material quality loss and nutrient damage caused by the presence of liquid water.

Small Freeze-Drying Machines Characteristics

1.Compact and portable. The small freeze-drying machine has a small volume, light weight, and is easy to carry and use.

2.Easy to operate: Most modern small freeze-drying machines use touch screens or rotary control panels, and users only need to set parameters such as temperature, time, and vacuum degree to start the equipment. Some high-end models are also equipped with intelligent control systems that can automatically adjust working parameters to meet the drying needs of different materials.

3.Efficient and energy-saving.By optimizing the heat conduction structure, adopting efficient vacuum pumps and refrigeration systems, small freeze-drying machines effectively reduce energy consumption and operating costs.

Application

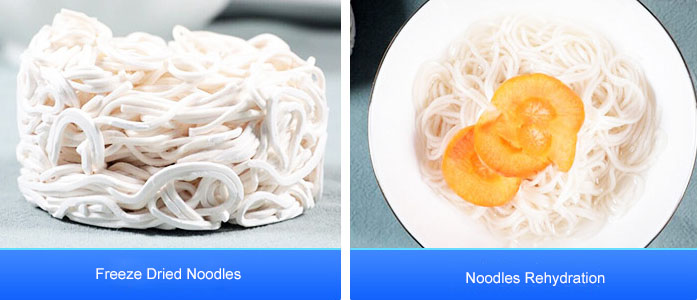

In food processing, freeze vacuum dryer can effectively preserve the nutritional content, color, flavor, and taste of food. Freeze dried fruits, vegetables, meat, seafood and other products are not only convenient for storage and transportation, but also can basically restore their original form and taste after rehydration, which is deeply loved by consumers. For example, freeze-dried fruits such as strawberries and blueberries have a crispy texture and can be used as leisure snacks.

Inquire Now

Contact Us

Request a Quote

Links:

Copyright © Shandong Heying Machinery Technology Co., Ltd. 2024 All rights reserved